What is the optimal solution for identification?

Specimen identification in laboratories, biobanks, and manufacturing facilities is a critical factor in ensuring overall efficiency, productivity, and traceability.

There are several approaches to sample identification, and a proper assessment should be made to determine which method is most appropriate. Samples stored at ultra-cold temperatures cannot be easily retrieved, and reconstructing identification methods involves a great deal of effort and loss.

In this article, we will introduce the characteristics and direction of the three main types of specimen identification methods.

Identification labels

Label-based identification is the gold standard for sample management. Management often starts on a small scale, and labels are a reasonable option as they require less initial investment. No special investment is required; all you need is a label printer (thermal transfer or direct thermal) and a barcode reader.

Advantages

- In addition to ultra-low temperature environments (-80c to -196c), there are a variety of functional labels such as chemical/organic solvent resistance, autoclave resistance, adhesion to frozen surfaces, and tamper resistance, making it flexible to suit your operation. You can choose.

- To suit the shape and size of containers, from small containers such as PCR tubes and cryotubes to freeze boxes, IVF straws, pathological specimens, metal racks, and various bottles.

Problems

- Plastic gloves must be worn to prevent cross-contamination, infection, and cold burns from ultra-cold samples. Applying labels while wearing gloves is a very stressful job, and there are cases where labels need to be reissued due to applying errors.

- Additionally, if procedures are not properly managed, there is a risk of mislabeling or mixing up labels.

Solutions

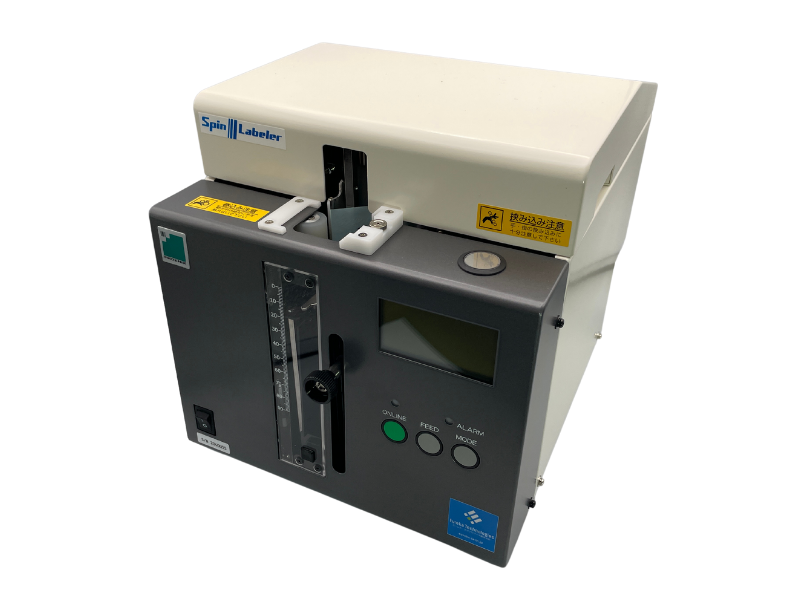

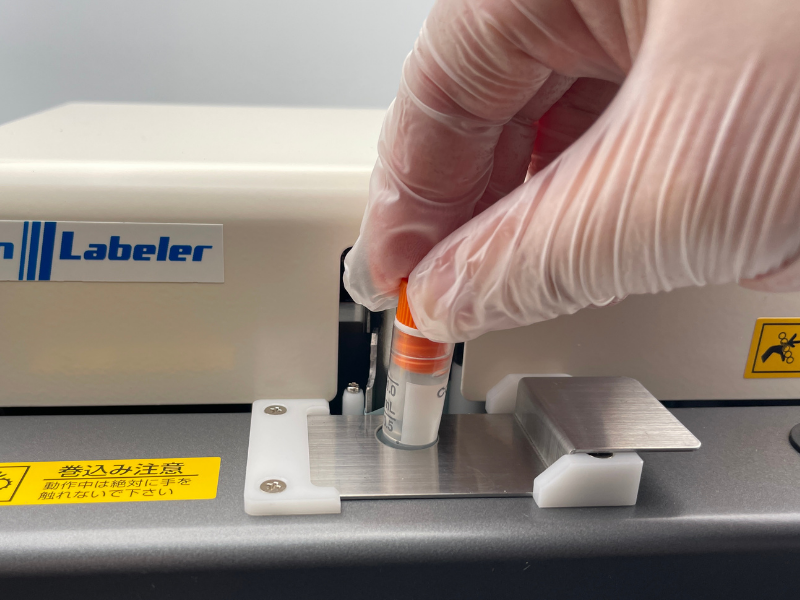

Automatic labeling systems are becoming popular to solve these problems. This product can print and apply labels at the same time, making it suitable for testing companies that handle large numbers of samples or for the needs of manufacturing their own reagents and test kits.

SpinLabeler, semi-automated tube labeler

2D barcoded tubes

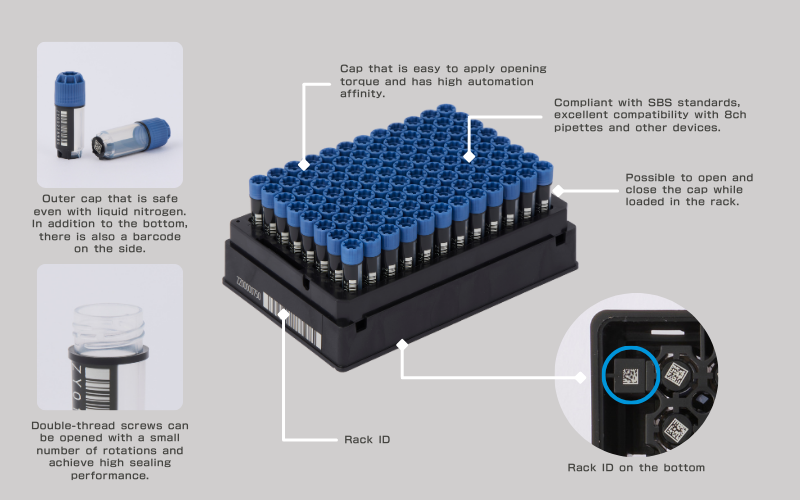

2D barcoded tubes, also called storage tubes, are tubes created for sample management. Tubes can be loaded at high density on a tube rack with a microplate format called the SBS standard.

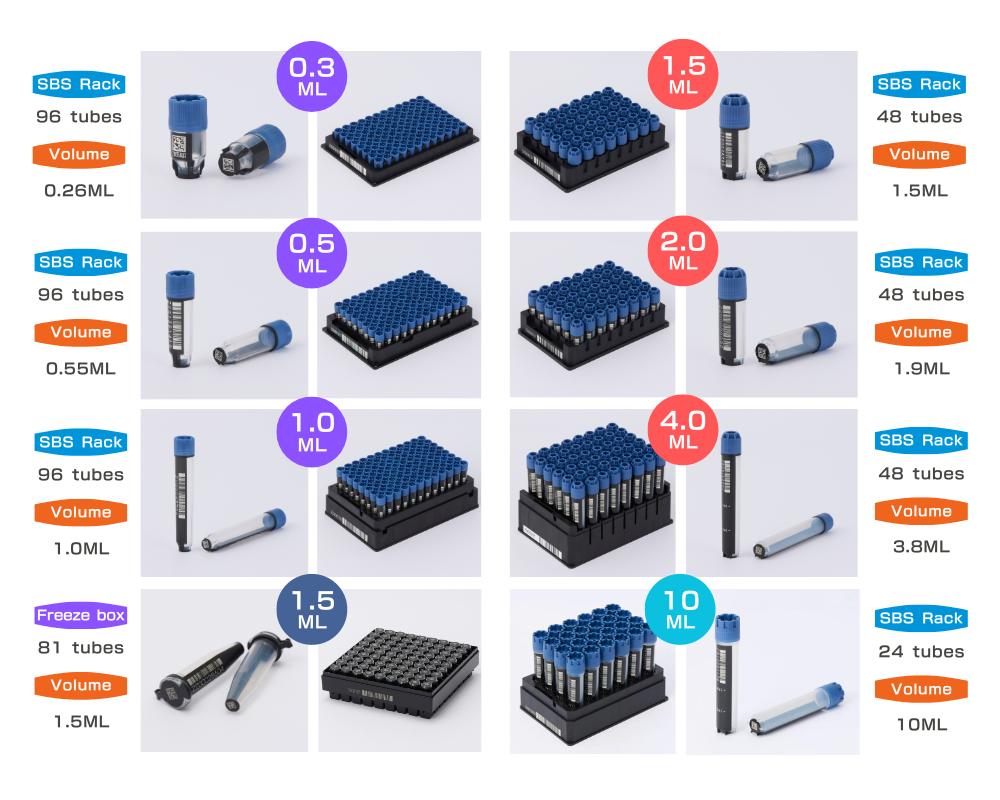

Depending on the capacity of the tubes, the number of tubes in a rack can be roughly divided into categories such as 96 (about 0.3 to 1.4 ml), 48 (about 1.5 to 4 ml), and 24 (5 to 10 ml).

Advantages

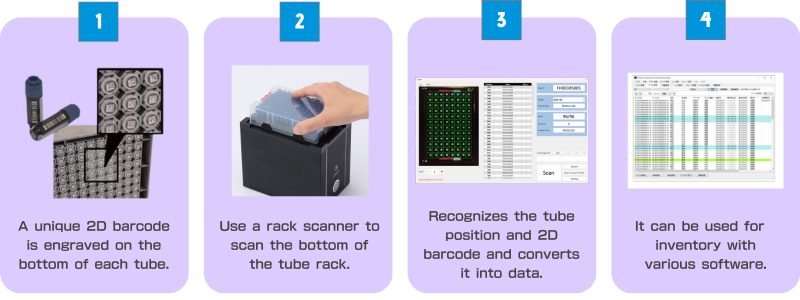

- A 2D barcode is engraved on the bottom (and also on the side) of the tube, and when loaded in a rack, a dedicated rack scanner can capture all information and location within the rack at once.

- When many specimens must be received or taken out at once, the specimens can be identified quickly and reliably.

- 2D barcodes are IDs that are consistently managed by the manufacturer, and no two IDs are the same, so samples can be uniquely identified.

- The SBS standard is widely used, and for 96 tubes, the rack footprint and pitch between tubes are identical to a 96-well microplate.

- It is highly compatible with assays using 8-channel pipettes and automated pipetting workstations.

- It is suitable for large-scale testing and screening because it can be seamlessly applied to component fractionation processing of serum and plasma from whole blood, PCR, and next-generation sequencing (NGS) processing.

Problems

- 2D barcoded tubes were designed from the perspective of how to store and manage samples at a high density. In particular, in the case of 96 tubes, the diameter of the tubes is very small, about 8 mm, and it is not suitable for opening and closing the caps manually. In order to open and close caps efficiently and reliably, it is necessary to use devices such as automatic decappers, which leads to increased investment.

- The tube-specific 2D barcode is an ID issued by the tube manufacturer, so it must be linked in the data to correlate with the sample ID that the user wants to manage.

- Unlike identification labels, it is not possible to identify or determine the sample information at a glance, and a procedure is required to query the sample ID based on the tube ID using sample management software.

- In recent years, tube capacities have become available in a wide range of 0.3 to 10ml. However, vessel selectivity is still not the same as for regular tube samples.

- One of the issues is that the price of the tube alone is somewhat high in return for the added value of imprinting a 2D barcode.

Solutions

Utilizing 2D barcoded tubes and increasing productivity requires the use of appropriate identification equipment and tools. While there are more expensive automation products on the market, we offer cost-effective assistance products like below.

cobaco S, Whole rack 2D scanner

cobaco L, Whole rack 2D scanner

Tube picker & decappder with stand

Contactless identification using RFID

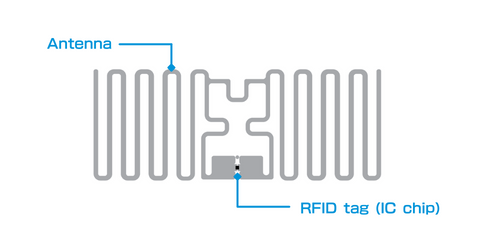

RFID is an abbreviation for Radio Frequency IDentifier, and is a general term for technology that uses short-range wireless communication using electromagnetic fields and radio waves to exchange information from tags (IC chips) that hold information. In recent years, it has become popular mainly in the apparel and logistics industries, and is becoming one of the mainstream in the next-generation automatic recognition field.

Advantages

- Until now, the only way to identify samples was to read barcodes in line-of-sight conditions. Using RFID, multiple samples can be identified at once without contact using radio waves and magnetic fields, even if the samples are hidden in a case or box.

- Since sample identification can be performed in an extremely short time, the risk of exposing temperature-sensitive biological samples such as cells, blood, and tissues to room temperature can be minimized, and the throughput of the series of processing can be improved.

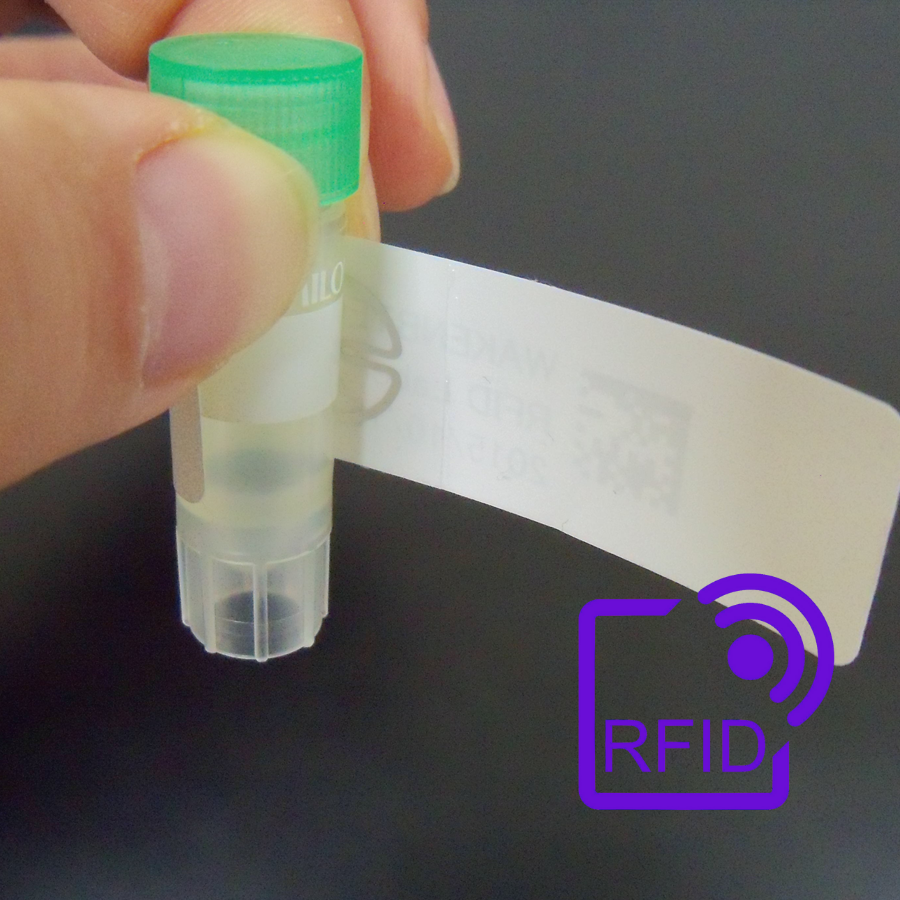

- Label solutions that embed RFID tags can expand sample management using conventional identification labels, so changes can be made without major changes to workflows and standard operating procedures (SOPs).

Problems

- In recent years, it has become more widespread in the supply chain, but the issue is price. Cost increases due to additional processing such as embedding RFID tags in identification labels are unavoidable, and this is one of the challenges for widespread use.

- RFID uses electromagnetic fields and radio waves to communicate with tags. There are various types of RFID tags that take into account the characteristics of the radio wave range (reading distance), the shape, size, and content of the target to be identified.

- Samples are often very small, such as cryotubes or vials, which limits the selection of suitable RFID tags. Additionally, many of them are stored in ultra-low temperature environments ranging from -20 to -196 degrees Celsius, so there are challenges that must be overcome, such as temperature resistance and reading performance at ultra-low temperatures.

- Even though RFID tags can retain data permanently, there is also the problem that they cannot be guaranteed 100% forever because they are electronic components.

Solutions

We have been working on solving these challenges for several years. After evaluating the most suitable RFID tags from the market, we actually stored the samples at liquid nitrogen liquid phase temperature (196℃) for over 3 years, and periodically removed samples and repeated 100% testing.

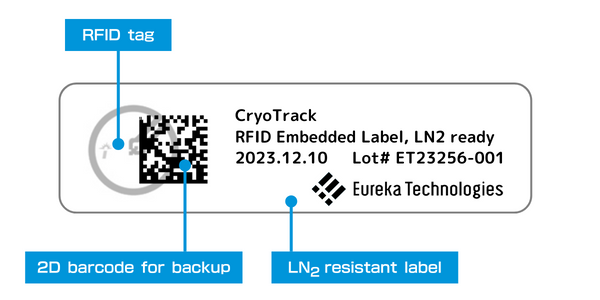

As a result, we succeeded in developing an RFID tag-embedded label that guarantees high durability and reading performance, as well as a reader that can automatically recognize 100 samples at once, and are currently in the process of actual adoption and operation.

Regarding data integrity of RFID tags, a 2D barcode is printed on the label to ensure data redundancy. Even in the unlikely event that the data in the RFID tag is lost or damaged, the data can be preserved using conventional barcode identification.

CryoTrack, RFID embedded lables