ROBOTUBE, Excellent next-generation microtube

Problem of microtubes

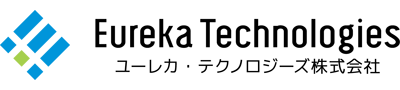

- Handwritten identification

Microtubes are usually identified by handwriting on the circular cap with a permanent marker. However, they tend to disappear during disinfection, and are prone to typographical errors and identification errors (I and 1, O and 0, etc.). - Stress of opening and closing the cap

Polypropylene microtubes require force to open and close to ensure a tight seal. There is also a risk of finger pain and tendonitis due to continuous opening and closing work. - Risk of contamination and infection

Since force is required to open and close, there is a risk that the liquid inside the tube may splash or aerosols may be generated when the tube is opened. - Low affinity for automation

When used in automated systems, especially dispensing workstations, the dispensing tip must be handled carefully to avoid interference with the cap. - Risk of mix-up

Since identification can only be done with the human eye, there is a risk of confusing the target sample.

Solution

What is ROBOTUBE?

ROBOTUBE is the first product in history to have a barcode and ID laser engraved on the top, sides, and bottom of a 1.5ml microtube. This is a pure Japanese product that overcomes the issues and problems of conventional polypropylene microtubes and pursues further advantages.

5 advantages of choosing ROBOTUBE

1. Establish traceability with barcodes

Each tube is laser engraved with a unique barcode that has been verified at the manufacturing factory. There is no need for cumbersome handwriting or labeling, and specimens can be reliably identified, eliminating the risk of mix-ups.

- Cap/bottom: 2D barcode

- Side: 1D barcode + human readable numbers

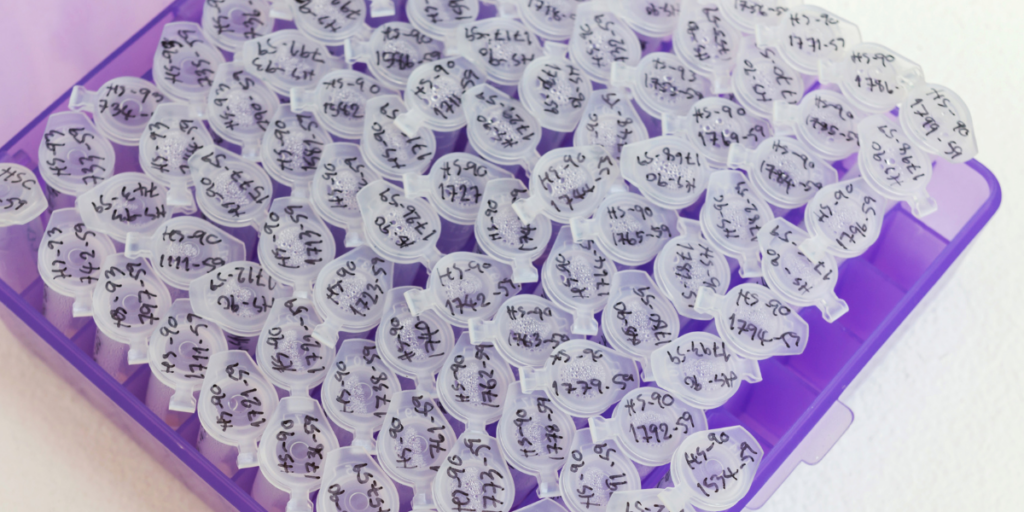

2. High affinity for labo-automation

Using 2D barcodes on the top and bottom, the position in the storage tube rack and sample information can be automatically linked. High-throughput automation can be achieved without errors.

3. Extremely smooth opening and closing

ROBOTUBE uses TPE (thermoplastic elastomer) to achieve extremely smooth and reliable opening and closing of the cap. Your fingers and hands won’t hurt even when handling many tubes.

4. Shipped with cap sealed

All tubes are shipped sealed. Therefore, individual tubes are not exposed to the outside air after opening the bag, eliminating the risk of external contamination and cross-contamination.

5. Strict quality control

All products are manufactured in Japan. The air cleanliness of our products is in the ISO class 6 area, and we are committed to a stable supply of high quality products under a strict quality control system.

What is TPE?

Thermoplastic elastomer (TPE) is a polymeric material with rubber-like elasticity. It is resistant to deterioration, has good processability, and has excellent heat resistance, cold resistance, and chemical resistance, and is widely used in the medical field for parts for intravenous drips, infusions, bags, and tubes.

Variation

ROBOTUBE

ROBOTUBE, 1.5ml microtube

Black, with barcode

ROBOTUBE, 1.5ml microtube

White, without barcode

Accesories

81 Freeze box

Magic-Rack 24

Magic-Rack 16

Magic-Rack cool 24

Case Study

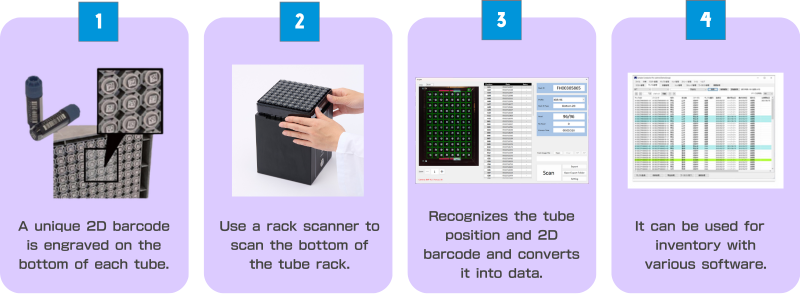

Using whole rack 2D scanner

By using the Whole Rack 2D Scanner, you can output the data of the rack location and tube ID. This data can be used in dispensing workstations and sample management software to ensure reliable processing.