Breaking away from dry ice, low-temperature cold packaging

The use of dry ice to store and transport biological samples is widespread, and its usefulness is undeniable. However, there are several issues with cold chain operation, not only in terms of environmental impact but also in supply chain continuity. In this article, we will introduce the characteristics of dry ice and our new cold storage approach.

Problems with dry ice

Dry ice has a very low sublimation temperature of -78.9℃, making it an excellent means of easily keeping things cold for long periods of time. However, several issues have come to light in the biotechnology and life science fields.

- management cost

Dry ice must be purchased from a specialized vendor or expensive manufacturing equipment must be installed, and care must be taken to ensure and manage the required amount at all times. - Preparation effort

In order to improve the cooling effect, it takes time and effort to crush the block of dry ice with a hammer. Pellet (nugget) forms do not have this problem, but are somewhat more expensive and last less long. - Oxygen deficiency risk

When using dry ice, consideration must be given to the risk of oxygen deficiency due to the carbon dioxide generated. - Risk of rupture

Dry ice expands by 800 times at room temperature. If you seal a dry ice container, there is a risk that the container will burst due to the expanded carbon dioxide. - Dry ice fog

Since crushed/pelletized dry ice has a large sublimation surface area, moisture in the air condenses and turns into ice, creating a dense fog. Visibility becomes poor and work efficiency decreases. - Volume reduction due to sublimation

The volume decreases as the dry ice sublimates. Therefore, it is necessary to pay attention to the amount of dry ice so that the object is kept sufficiently cold during the cooling period. - Difficulty in quality control

Dry ice is often produced as a by-product, making it difficult to guarantee its quality and cleanliness.

Cooling capacity of dry ice

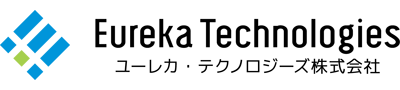

Dry ice is only effective at close range. The figure below shows the temperature evaluation of dry ice. Crushed dry ice was placed on the bottom of a Styrofoam box, and the temperature was measured at the bottom of the dry ice and at distances of 2 cm, 5 cm, 8.5 cm, and 17 cm from the surface.

Even at a distance of only 2cm, the temperature was -50 to -60℃, and a distance of 5cm or more did not provide a satisfactory cooling effect. For this reason, when using dry ice, the specimen must be wrapped in dry ice.

Cold chain utilization using Phase Chane Material

Phase Change Material (PCM) is a material that stores heat, and it transfers a large amount of thermal energy (latent heat) when changing phase between solid and liquid. In collaboration with Tamai Kasei, our company has been working on the development of cold packaging using PCM, which has a melting point of -70℃. By applying this technology, it has become possible to utilize a sustainable cold chain that is environmentally friendly and can be used whenever needed.

Advantages of PCM

PCM has many advantages compared to dry ice.

- Cooling effect in ultra-low temperature range

The effective cooling temperature is -50 to -65c, and it stably exhibits performance comparable to dry ice. - Can be used repeatedly

Can be pre-chilled in an -80c freezer. The pre-cooling time is 40 hours, and it can be used repeatedly for 3 years after opening without any limit to the number of times it can be used. - Exterior can be wiped clean

The package can be wiped down with a disinfectant such as 70% ethanol. - Safety and security

There is no carbon dioxide generation and the composition of PCM does not contain any hazardous materials, so you can rest assured. - Usage and operation according to scale

The size of one sheet is W140 x D220 x H27mm, and the number of sheets can be adjusted according to the amount and size of the object. We also offer large-sized cold storage materials.

CryoTrack System

The CryoTrack system is a cold chain cooling package developed by us. We provide an effective and highly productive cold storage method with a lineup suitable for applications using CV-70 PCM, vacuum insulation panels (VIP), and high-performance insulation materials.

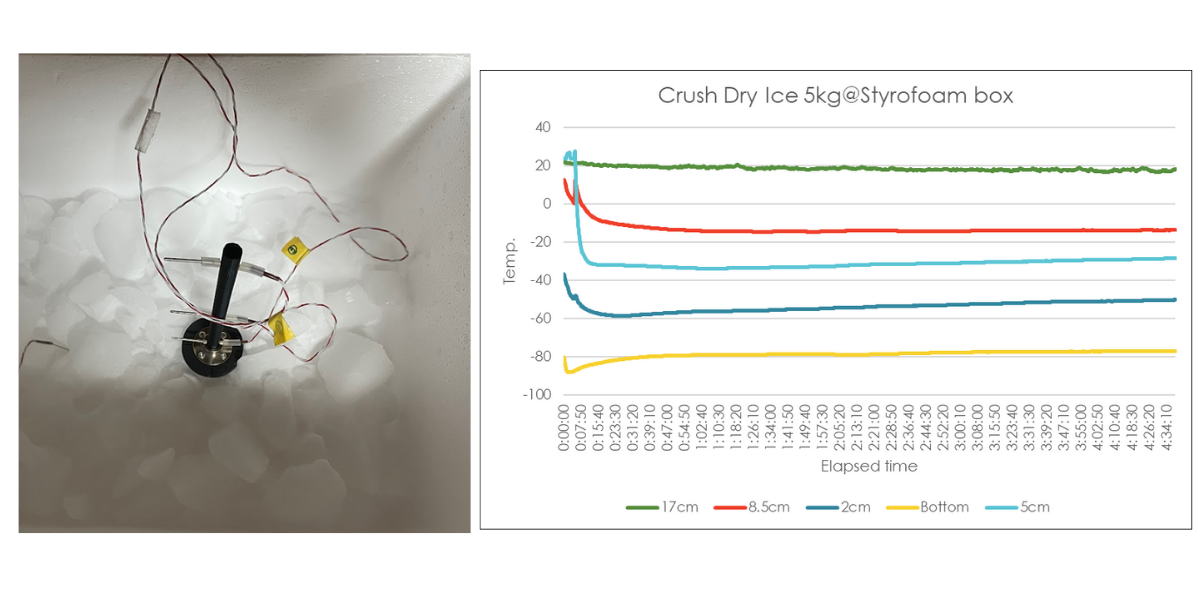

CryoTrack Porter

- A tool for transporting frozen samples within a facility. Using one or two CV-70 PCMs, it is possible to maintain temperature at -60c for more than 5 hours.

- It is compact and suitable for transport and work within the laboratory or via pass boxes.

- In addition, if you use the CV-2 PCM, it can be maintained at 4c for more than 6 hours, so it can also be used for dispensing work in a clean bench.

Operation example

- Sample transfer from liquid nitrogen containers and freezers

- Freeze box transport

- Transport samples in the cooling block of the Controlled-Rate Freezer

- Dispensing the sample while keeping it cold at 4c

CryoTrack Station

- Intended as an in-house frozen sample workbench. By using 13 pieces of CV-70 PCM and radiative cooling from 5 sides, an effective space of W390 x D200 x H120mm can be maintained at -50c for more than 3 hours.

- In the work space, two 135mm square freeze boxes can be placed side by side, allowing you to perform tasks such as organizing samples.

- It can also be cooled from the top using three additional PCMs. If you close the included magnetic lid, it can be maintained at -50c for over 24 hours.

Operation example

- Inventory and organization of stored samples, transfer work between boxes

- Quality inspection, inserting supporting documents before shipping

- Labeling and visual inspection of frozen samples

- Sample evacuation and backup use in case of freezer failure

CryoTrack Carrier

- This is a package for hand-carried transportation using dry ice, such as transporting specimens between facilities or from clinics to laboratories.

- This carry bag uses vacuum insulation (VIP) and high-performance insulation material, and can be carried with a shoulder strap.

- The top of the bag has a pocket where you can store a temperature logger.

Operation example

- Transportation of samples between facilities (vehicles, public transportation, etc.) for approximately 8 to 10 hours

- Ultra-low temperature transportation in situations where dry ice is difficult to use

- Transport of cryogenic specimens within the facility